Oak Tree Engineering, LLC

Pre-Engineering and Detail Engineering

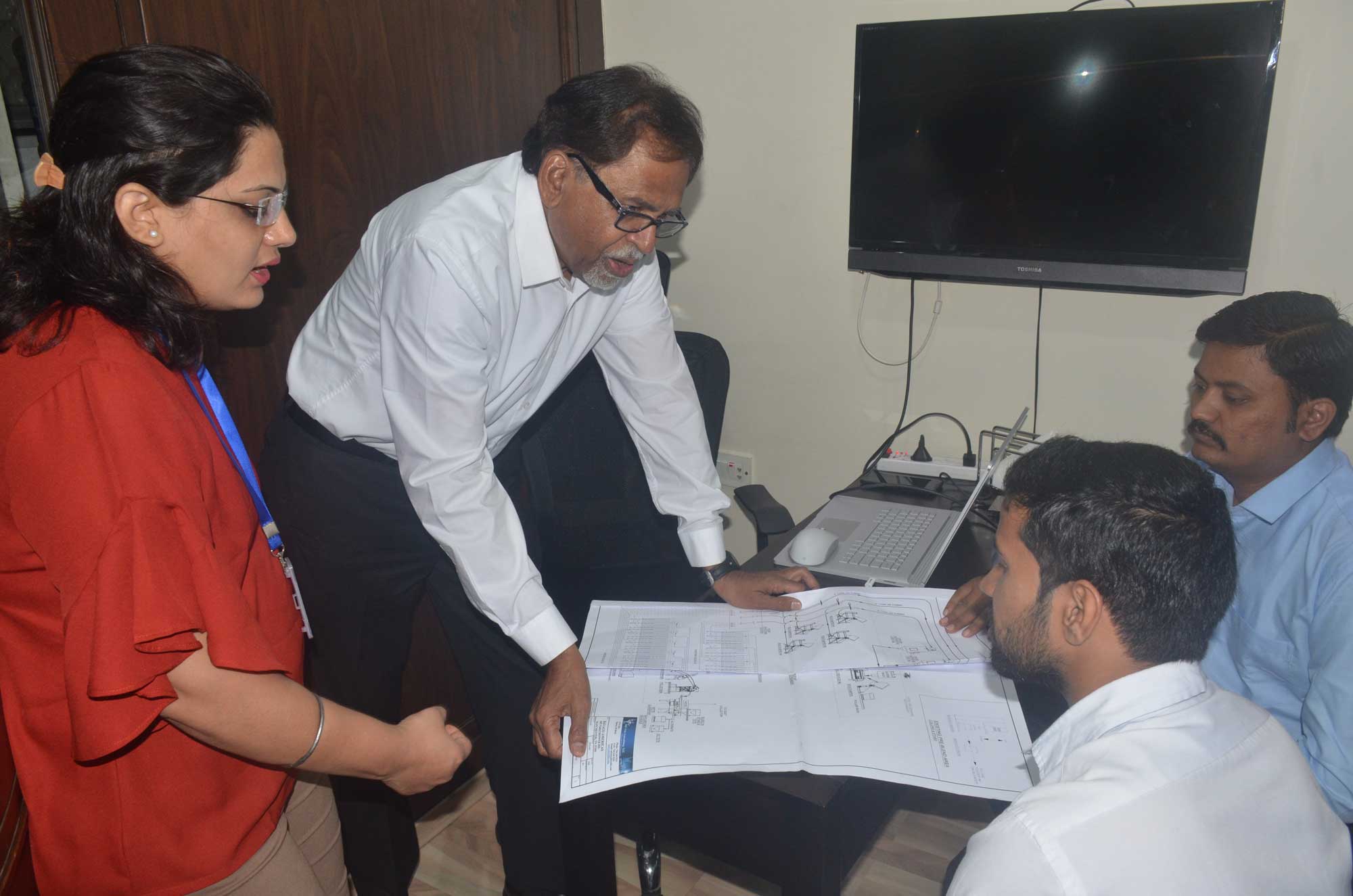

Engineering and Design are our core competencies. Between USA and India offices, we have a superb team of engineers and designers who work together, using our global experience and resources to produce high quality, technically accurate, and meticulously organized engineering drawings and documents.

Our experience in thermoplastic compounding technology and years of experience in field helps us resolve complex problems and provide appropriate engineering solutions to our clients.

We have developed most efficient and practical systems to manage challenging engineering projects, in close coordination with client’s engineers and managers, to deliver required engineering drawings and documents consistent with project schedule. Our engineering service deliverables include:

- PFD’s and P&ID’s

- Utilities Matrix (Power, Air, Water, Nitrogen)

- Project schedule and budget

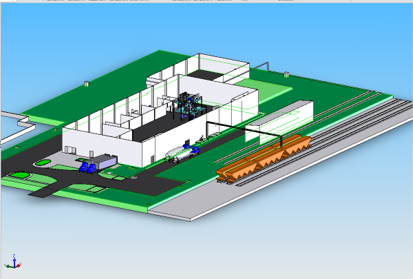

- Plant layout

- Equipment list and specifications

- RFQ’s

- General Arrangement drawings

- Structural Drawings (Mezzanines and Platforms)

- Material Handling Systems (piping, layout, loading/unloading)

- Storage Systems (silos, tanks, racks)

- Fabrication Drawings

We start the engineering and design process with pre-engineering whereas conceptual design documents and drawings are developed in close coordination with customer’s engineers. Once the basic design and setup is approved, detail engineering work starts following project scope, parameters, and protocols agreed with the customer. Some common tasks included in Pre-engineering and Detail Engineering phases are listed below.

Pre-engineering

- Develop overall project scope and baseline schedule with customer.

- Develop concept plant layout.

- Preliminary Process Flow Diagram (PFD)

- Site visit by OTE senior managers and meetings with Client’s staff, builders, and other stake holders.

- Preliminary equipment list.

- Equipment placement and material flow orientation with future expansion considerations.

- Utilities – Power, Water, Air, Nitrogen – calculations and preparation of ‘Utility Matrix’.

- Emissions calculations for permits and licenses as required

- Waste-water disposal calculations and proposed plan as required.

- Production estimates and calculations

Detail Engineering

- Prepare and submit to the client ‘Basis of Design’ documents for review and approval.

- Prepare final process and support equipment, including infrastructure and utilities, identification, configuration, and specification details in accordance with customer’s requirements.

- Prepare following final working documents for customer review and approval:

- Structural drawings (mezzanine, platforms, etc.) as needed.

- Process Flow Diagrams (PFD’s)

- Piping and Instrumentation Diagrams (P&ID’s).

- Environmental, Health and Safety (EHS) related documents and drawings as necessary.

- Basic Electrical Single Line Diagram (SLD).

- Dust collection system documents as necessary.

- Material handling detail engineering, design, and drawings.

- Water supply and disposal drawings (including floor drains details.

- Other detailed layouts & drawings (2D and 3D) as requested and/or required.

- If responsible, analyze, compare bids, negotiate price and issue PO’s to selected vendors

- Review all vendor drawings and documents including modifications and revisions.

- Resolve technical issues and provide field engineering support and advice as necessary.

- Organize structural, mechanical or soil testing on behalf of client where necessary.

- Assure all Operating and Maintenance Manuals for major equipment are available.

Additionally, OTE helps and supports customers in obtaining environmental and other regulatory permits and licenses such as emissions and effluents. We collaborate with local authorities, conduct engineering calculations, and develop custom design alternatives to satisfy the specific requirements applicable at plant location. We work closely with authorized and qualified service providers to assure that loading calculations are checked, validated, and all drawings and documents duly certified and stamped for all mezzanines and platforms before releasing them to construction contractors.

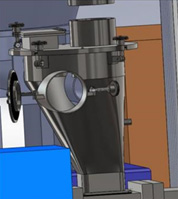

Custom Parts Design & Fabrication

Our goal in setting up any extrusion line always remains to deliver a safe, functional, and cost-effective installation. Costs are not only the initial costs of equipment and installation but also long-term operational cost. OTE works closely with customer’s engineers and operators to deliver the design and arrange equipment in a way that meet their expectations of safety and functionality while reducing downtime in clean-up and changeovers. This sometime requires custom parts and fixtures that are not available off the shelf. With our experience in this field and our extensive networks of vendors, suppliers, and fabricators, OTE has the ability to provide complete designed and fabricated special parts and fixtures for optimization of functionality of the system.

Our goal in setting up any extrusion line always remains to deliver a safe, functional, and cost-effective installation. Costs are not only the initial costs of equipment and installation but also long-term operational cost. OTE works closely with customer’s engineers and operators to deliver the design and arrange equipment in a way that meet their expectations of safety and functionality while reducing downtime in clean-up and changeovers. This sometime requires custom parts and fixtures that are not available off the shelf. With our experience in this field and our extensive networks of vendors, suppliers, and fabricators, OTE has the ability to provide complete designed and fabricated special parts and fixtures for optimization of functionality of the system.

Feed Throat Hopper

3D SolidWorks Model

3D SolidWorks Model

Feed Throat Hopper Fabricated